⭐️ Get Upto 10% OFF on Your First Order – Order Today! 🛒

⭐️ Get Upto 10% OFF on Your First Order – Order Today! 🛒

Menu

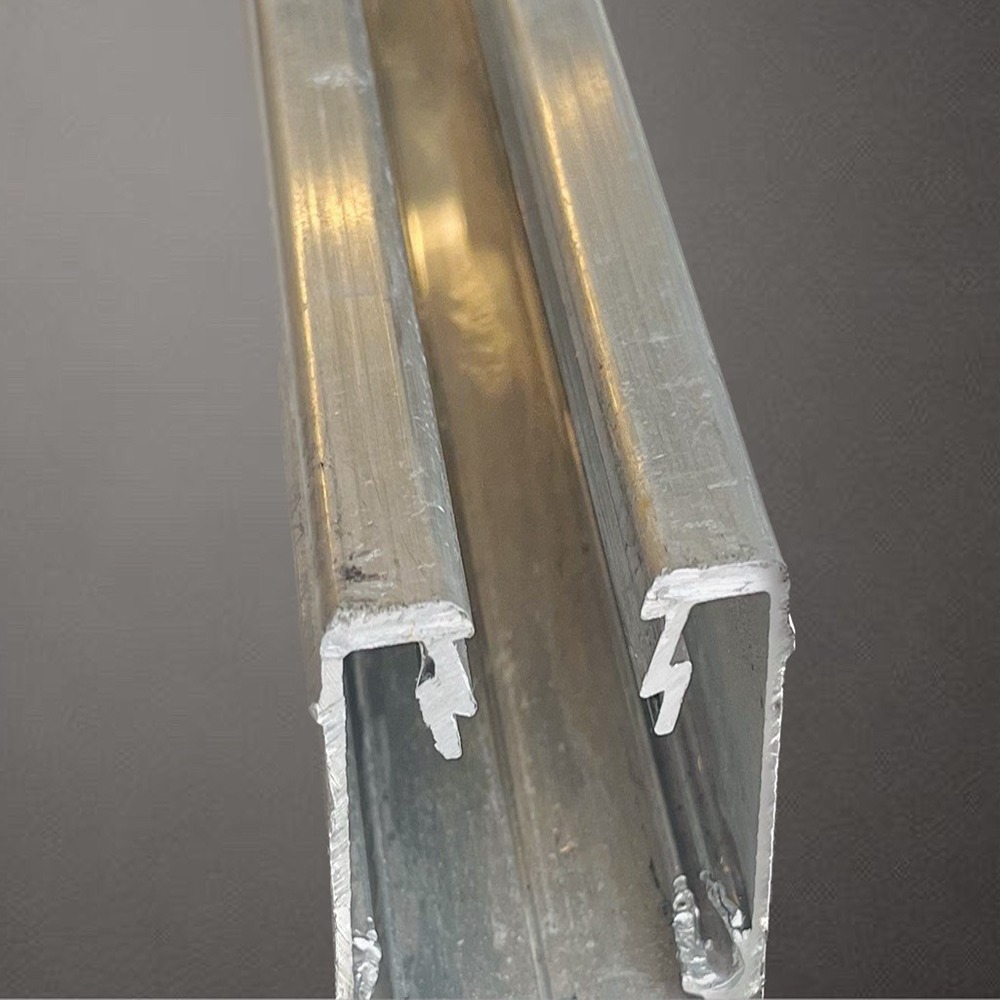

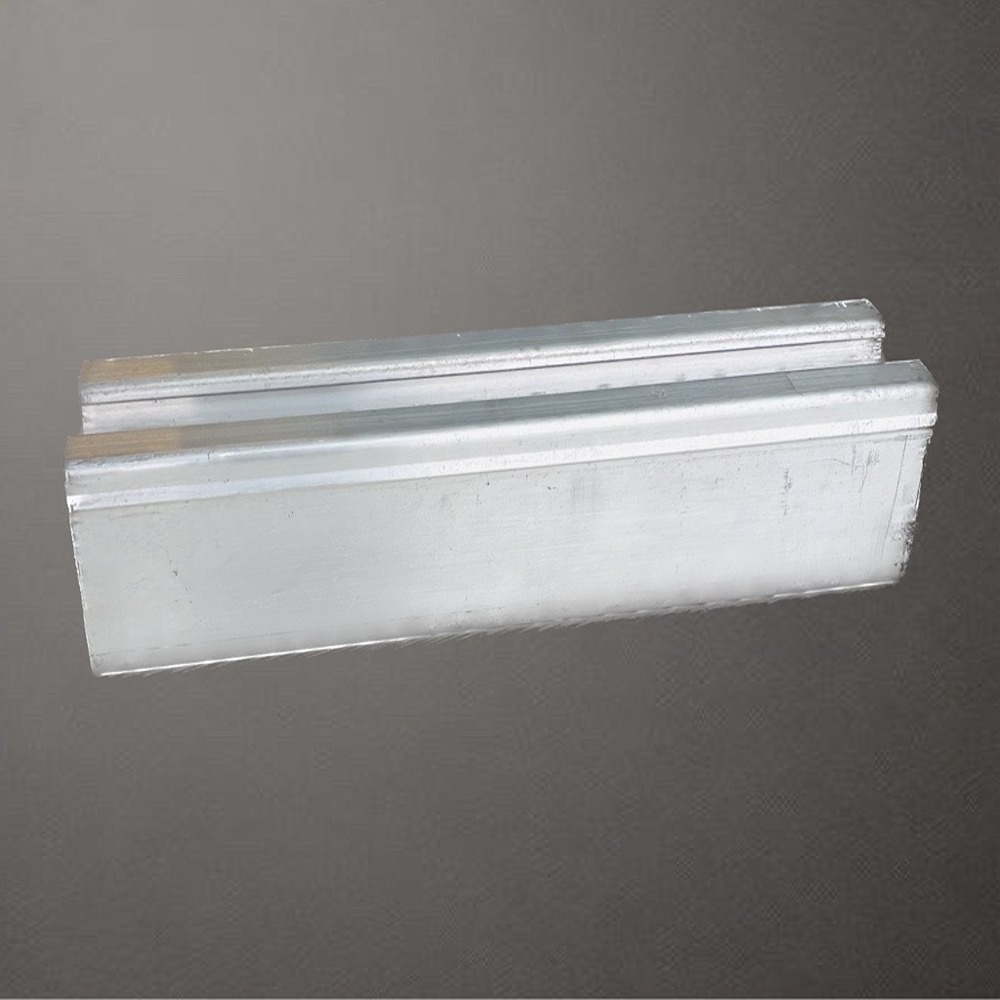

UPD ( Aluminum U profile )

₹145.00

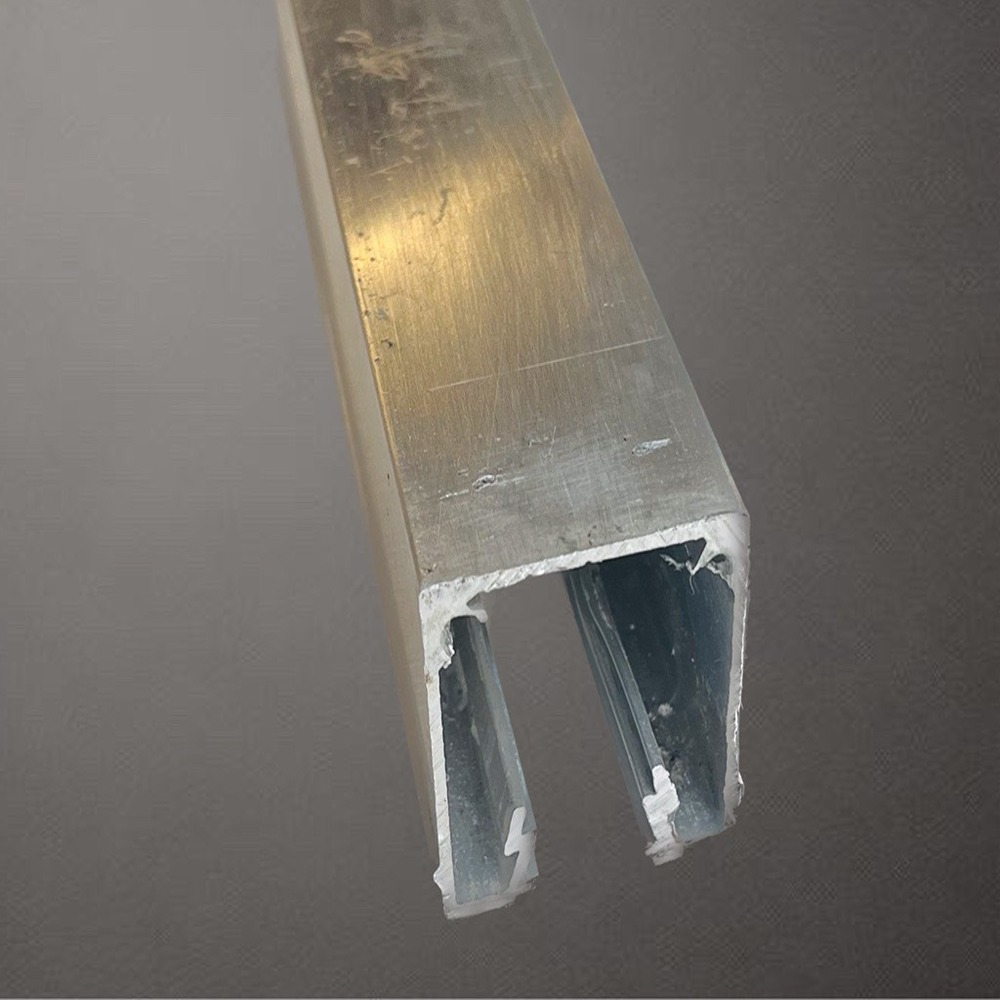

- Material: Aluminum – Typically made from lightweight and corrosion-resistant aluminum. Aluminum connectors are known for their strength and durability.

- Design: The connector is designed to fit between two multi-cell polycarbonate sheets, creating a stable and tight joint. It often has a profile that matches the shape of the sheets, ensuring a secure fit.

- Compatibility: Designed to fit standard multi-cell polycarbonate sheet profiles and dimensions, ensuring a proper and secure connection.

- Weather Resistance: Aluminum connectors are naturally resistant to corrosion and weathering, making them suitable for outdoor applications.

- Color Options: Available in various finishes, including natural aluminum, white, or custom colors to match the aesthetic requirements of the installation.

- Installation: Typically designed for easy installation, with pre-drilled holes or slots for fastening with screws or bolts.

- Dimensions: Offered in various sizes to accommodate different sheet thicknesses and profiles.

- Load-Bearing Capacity: Engineered to provide structural support, distribute loads evenly, and prevent sagging or damage to the sheets at the joint.

- Aesthetic Finish: Provides a finished appearance to the joint between the polycarbonate sheets, enhancing the overall look of the installation.

- Application: Suitable for use in roofing, cladding, and other applications where multi-cell polycarbonate sheets need to be securely and tightly connected.

- Durability: Designed to withstand outdoor exposure and temperature fluctuations without corroding or weakening.

- Protection: Provides structural integrity to the connection point, ensuring long-term performance, and can also help seal the joint against moisture infiltration.

| Grade | Essentials |

|---|

Be the first to review “Aluminum Connector” Cancel reply

Related products

Aluminum Clet

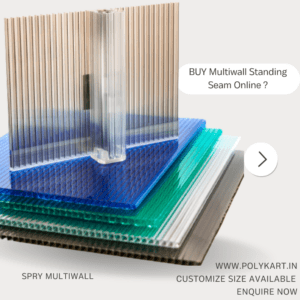

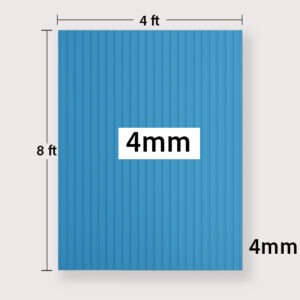

₹33.00 Select options This product has multiple variants. The options may be chosen on the product pageMultiwall Standing Seam ( Standard Size 8FT x 3FT )

₹1,500.00 Select options This product has multiple variants. The options may be chosen on the product pageSale

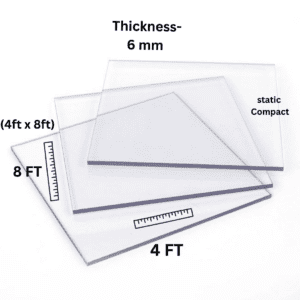

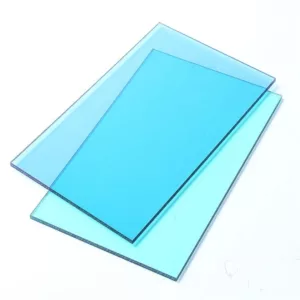

Coxwell Solid 6mm Static Compact Polycarbonate sheet

Sale

Reviews

There are no reviews yet.